This course provides students with the opportunity to employ their cumulative skills and talents in a chosen area of focused study. Each student must declare an area of interest that will be the basis of a unique product or project, requiring a series of scheduled tasks to complete. This culminates with a presentation and critique, portfolio and Year End Show.

- Teacher: Bruce Fitz-Earle

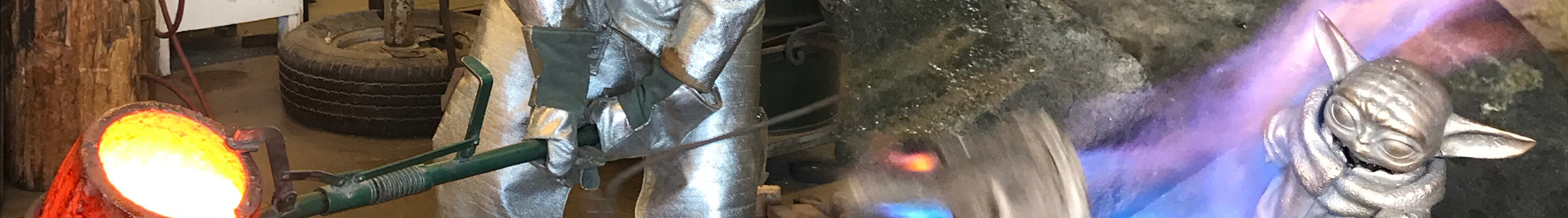

Molding and Casting for Advanced Manufacturing: Students are introduced to the basic design principles and techniques used for various molding and casting techniques. Emphasis is on the practical side and will include designing for and implementing projects utilizing vacuum forming, metal casting and various mold making techniques.

- Teacher: Bruce Fitz-Earle

This course is delivered in a hands-on, workshop-style format that mirrors how real startups take shape. Students learn the fundamentals of startup business processes by creating and refining a Business Model Canvas, building a clear, practical foundation for a viable business idea. Through in-class activities, applied exercises, and insights from guest speakers with real startup experience, students develop and test their ideas as they go. The course culminates in the creation of a pitch deck and a live presentation of each startup concept to an audience, with structured feedback to support learning, iteration, and improvement.

- Teacher: Jeanne Kim

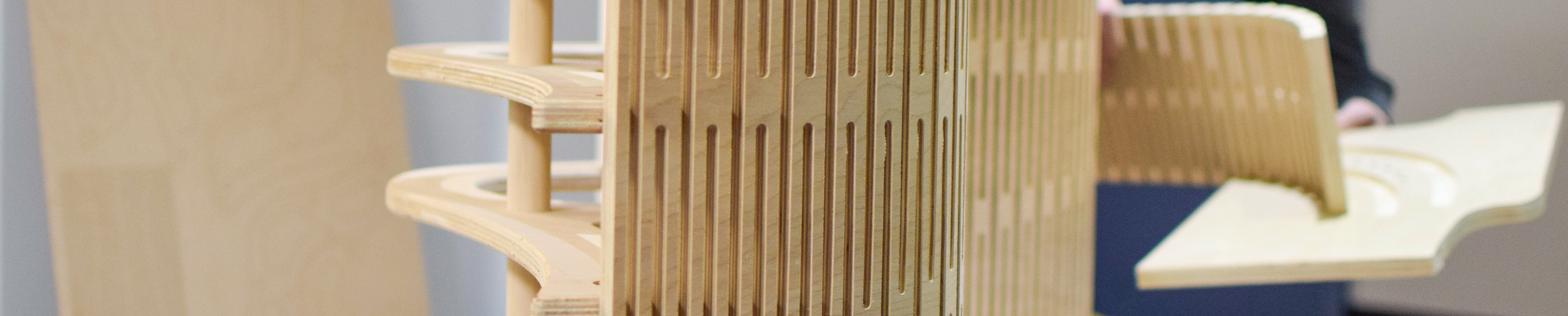

DFAB 107 Design for Subtractive Manufacturing: Design criteria for a variety of 2D subtractive manufacturing processes will be covered in this course. Students will gain additional skills in solid and parametric modeling as it pertains to subtractive manufacturing design criteria. Students will learn a variety of design techniques for subtractive technologies including 2D CNC milling, routing, and laser cutting.

DFAB 108 Subtractive Manufacturing 1: In this course students will learn standard operating and maintenance procedures for subtractive manufacturing machines, processes and workflows, including safe operation of all systems. Students will receive hands-on training on a variety of subtractive manufacturing technologies specifically, 2D CNC routing, milling, and laser cutting for wood, plastic, and other material mediums.

- Teacher: Shawn Curran

- Teacher: Kailey Allan

- Teacher: Bruce Fitz-Earle

Students will learn how to design for digital fabrication. Emphasis will be put on designing functional parts following industry design standards. This course will focus directly on 3D CAD applications and design practices. Students will gain knowledge in solid and parametric modeling as well as the migration between various workflows and approaches.

- Teacher: Kailey Allan

- Teacher: Max Beauchesne

DFAB 208 Sustainability and Adaptive Design allows students to apply digital design and fabrication techniques within the context of sustainable product design and adaptive design. Students will complete a series of projects using tools such as 3D solid and surface modeling, 3D scanning technologies, and experimental approaches to digital model generation. Digital models will be made physical through a variety of fabrication technologies which can include 3D printing, CNC milling, casting, molding and laser cutting.

- Teacher: Kailey Allan

DFAB 204 Computer Aided Design and Rapid Prototyping. Students will receive an introduction to advanced surface and solid CAD modelling software. Use CAD to create complex solid and surface models. Translate design files between multiple CAD softwares. Explore the relationship between design intent, form giving, and formal resolution through a rapid prototyping exercise.

- Teacher: Kailey Allan

- Teacher: Bruce Fitz-Earle

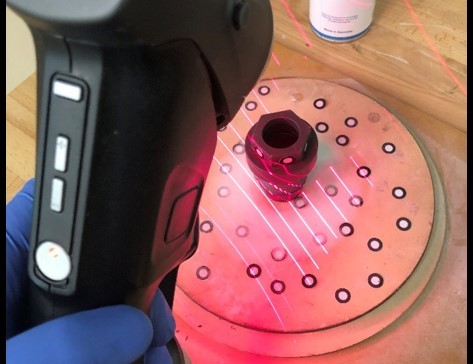

3D Scanning and Reverse Engineering. In this course students are introduced to reverse engineering where they will learn a variety of techniques including photogrammetry, LiDAR, structured light and machine probing. Students will then focus their learning on scan to CAD, metrology processes and product analysis.

- Teacher: Shawn Curran